Overall Introduction of Organic Pigment

What is pigment and dyes?

1.Pigment Definition

1.1 International Definition

Pigments are colored, black, white or fluorescent particulate organic or inorganic solids which usually are insoluble in, and essentially physically and chemically unaffected by, the vehicle or substrate in which they are incorporated. They alter appearance by selective absorption and by scattering of light. Pigments are usually dispersed in vehicles or substrates for application, as in the manufacture or inks, paints, plastics or other polymeric materials. Pigments retain a crystal or particulate structure throughout the coloration process.-defined By CPMA (The Color Pigments Manufacturers Association, Inc.),

Dyes are intensely colored or fluorescent organic substances only, which impart color to a substrate by selective absorption of light. They are soluble and go through an application process which, at least temporarily, destroys any crystal structure by absorption, solution, and mechanical retention, or by ionic or covalent chemical bonds.—defined By ETAD (The Ecological and Toxicological Association of Dyes and Organic Pigment Manufacturers). Both are of categories of colorant which definition is a substance used for coloring a material, sometimes also called coloration matter or coloring matter

1.2 Simplify Definition

Pigment refers to a class of organic matter that insoluble in water, not soluble in the use of media, but has been highly dispersed state of particles so that the colored matter is colored; Dye is dissolved in water or other solvent colorant, pigment and dyes solubility in water, as follows

Picture 1 pigment and dyes solubility in water,a-pigment, b-dye

1.3 Pigment Synonyms

When we talk about pigments, there are several synonyms of pigment might be mentioned, such as color pigment, colorant, coloration, coloring agent.

Pigment Classification

2.1. Classified by Chemical Structure

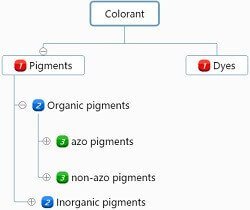

The pigment can be classified into organic pigments, inorganic pigments, organic pigments which can be divided into azo pigments and non-azo pigments, as picture 2 below

Picture 2 pigment classification

Organic pigments can classify into azo pigments and non-azo pigments, which azo pigments includes monoazo yellow, orange, diazo compounds, naphthol, naphthol AS, azo lake, benzimidazolone, Bisazo condensation, metal complexes. The non-azo pigments can further subdivide into pigments such as heterocyclic and fused ring including phthalocyanine, quinacridone, perylene and perinone, thioindigo, anthraquinone, dioxazine, isoindolinone and isoindoline, diketo-Pyrrole-pyrrole (DPP), triarylcarbonium, quinophthalone.

Inorganic pigments include titanium dioxide white, carbon and plant black, iron oxide, cadmium, lead chromate, chromium oxide green, ultramarine blue, iron blue, chrome green, phthalocyanine green, mixed metal oxides, bisovanadates, Manganese oxide (MNO).

| Organic pigments | Inorganic pigments |

| Azo pigments | Titanium dioxide white |

| Monoazo yellow and orange | Carbon and vegetable black |

| Diazo | Iron oxide |

| Naphthol | Cadmium |

| Naphthol AS | Lead chromate |

| Azo lakes | Chromium oxide green |

| Benzimidazolone | Ultramarine blue |

| Diazo condensation | Iron blue |

| Metal complex | Chrome green |

| Polycyclic pigments | Phthalo chrome green |

| Phthalocyanine | Mixed metal oxide |

| Quinacridone | Bi-vanadate |

| Perylene and perinone | Manganese oxide (MNO) |

| Thioindigo | |

| Anthraquinone | |

| Dioxazine | |

| Isoindolinone and isoindoline | |

| Diketo-pyrrolo-pyrrole (DPP) | |

| Triarylcarbonium | |

| Quinophthalone |

[accordion tag=p]

[accordion-item title=”Difference Between Organic and Inorganic Pigments” state=closed]

Compared with organic pigments, inorganic pigments have lower cost, simple production process and higher yield than organic pigments. Also excellent light resistance, heat resistance, and weatherability. Inorganic pigment is suitable for architectural coatings, glass, ceramics, rubber, and plastics coloring.

Compared with inorganic pigments, organic pigments are widely used in the fields of ink, paint, and plastic, due to a wide range of colors, bright colors, and bright hue. A very high tinting power is formed. Organic pigments can be prepared through the deep processing to meet different application requirements (such as high tinting strength, high transparency, high mobility, etc.) special commodity formulations, among them, high-performance. Organic pigments are with excellent light resistance, heat resistance, solvent resistance and other applications performance, in line with the high-grade inks, coatings and plastics areas coloring needs. As shown in Table 1 below

Table 1 Comparison of organic and inorganic pigments

Inorganic pigments | Organic pigments | |

| Varieties of chromatography | Less variety, narrow spectrum | More varieties, wider spectrum |

| Color characteristics | lower brightness, dark | Bright, bright |

| Tinting strength | low color strength | High color strength |

| Special dosage forms | less | A variety of commercial formulations |

| Heat resistance | Most are higher | Generally low, high-performance varieties have excellent heat resistance |

| Durability (light and weather resistance) | Most varieties are higher | High-performance varieties excellent durability |

| Acid and alkali resistance | Some species discolouration decomposition | Preferably, excellent |

| Solvent resistance | excellent | Medium to fine |

| Toxicity (heavy metals) | Some varieties of high toxicity (lead, chromium, mercury, etc.) | Non-toxic, low toxicity |

| Cost | Lower | Higher |

[/accordion-item]

[/accordion]

2.2. Classified by Chromatography

Pigment can be divided into red, yellow, blue, green, orange, violet, white, black, brown pigment; they are not all independent of each other.There is a certain internal relationship between colors, as we all known, a color is determined by three parameters, which are hue, chroma, value.

2.3. Classified by Application

Pigment can be divided into ink, paint, plastic and other pigments.

2.4. Classified by Color Index

The famous “Color Index” Color Index is a color classification method, pigment is classified into pigment yellow (PY), pigment orange (PO), pigment red (PR), pigment violet (PV), Pigment Green (PG), Pigment Brown (PBr), Pigment Black (PBk), Pigment White (PW), Metal Pigment (PM) according to Color Index.

2.5. Classified by Compound Contained

Pigment can be divided into organic pigments, inorganic pigments, which Inorganic pigments can be divided into oxide, chromate, sulfate, carbonate, silicate, borate, molybdate, phosphate, vanadate, Ferricyanides, hydroxides, sulfides, metals, etc.Organic pigments can be classified into polycyclic pigments such as azo pigments, phthalocyanine pigments, anthraquinones, indigoids, quinacridones, dioxazine, polycyclic pigments based on the chemical structure of the compounds.

2.6. Pigment Nomenclature

2.6.1 C.I. Generic Name or C.I.index

C.I. Common name, is the dye index (Color Index) or Generic name (Generic Name) abbreviation for each organic pigment, for example, C.I. Pigment Red 139; C.I. Pigment Red 179; etc.

2.6.2 CAS Number

Known as CAS RN, CAS registry number, also known as CAS # is a substance (compound, polymer materials, biological sequences (Biological sequences), mixture or alloy) unique digital identification number.

How does pigment work?

Mechanism of pigments is most pigments work by absorbing certain wavelengths of light. Other wavelengths are reflected or scattered, which cause you to see those colors.

Test of organic pigment?

(testing method of organic pigments in plastics)

Full shade

Full shade: based on a shade concentration of 0.2% pigment. White reduction: use standard depth 1/3 (SD 1/3) as white reduction, based on the respective pigment concentration to achieve 1/3 ISD based on 5% TiO2[/accordion-item]

Heat resistance

Heat Resistance in PVC-P

Resistance to heat was tested according to DIN 53775, soft calendered sheet was made, put the sheet in 180℃ oven for 30 minutes, and compare with sheet without heating, were assessed using the ISO 105-A03 grayscale (GS) for assessing staining, with GS 5 denoting no migration, GS 1 means poorest immigration.

Heat Resistance In Polyolefins,HDPE,PP,PS,ABS,PET,PC

Resistance to heat was tested according to DIN 12877 at SD 1/3 with 1 % titanium dioxide in the injection molding process. The values quoted are the temperature in ° C at which, after a dwell time of 5 min, a color change equivalent to a ΔE*ab = 3 (DIN 6174) is obtained.

Light fastness (HDPE and PVC-p)

Method 1: Lightfastness was determined using Xenon lamp exposure tests by the equivalent test methods ISO 4892-2. The samples were assessed against the 1–8 Blue Wool Scale which eight denoting the highest lightfastness.

Method 2: Accelerate aging testing, by ISO 105 B02, put Sample and Blue Wool Scale in xenon light which five times strong than sunlight, cover 1/2 of sample and Blue Wool Scale, till the sample color equivalent to

ISO 105-A03 grayscale (GS) GS 3 degree, then use the Blue Wool Scale to assess light fastness from 1-8.

Fastness to Migration

Migration resistance was determined by DIN 53775 by direct contact between the colored test sheet and a white, flexible PVC contact sheet. Assessed using the ISO 105-A03 grayscale (GS) for assessing staining, with GS 5 denoting no migration.

Weather resistance (HDPE and PVC-p)

Weather resistance was determined using Xenon light exposure tests by the equivalent test methods ISO 4892-2, assessed using the ISO 105 grayscale (GS) for assessing staining which 5 denoting no migration

Warping (HDPE)

Influence on the warping tendency of injection-molded HDPE articles was determined by ISO 294-4/ASTM D955. assessed using low, high, it(not tested)

How To Choose Organic Pigments for Plastic?

(A buyer’s selection guide of organic pigment)

How to choose Pigment Orange for Plastic?

[table id=67 /]

There are nine orange pigments suited for plastics, key features of these plastic orange pigments as below

Pigment Orange 64 is With high tinting strength, high hiding power, high saturation, good dispersibility, good properties, comply with food contact.

Pigment Orange 71 is with better transparency, high saturation, P.O.71 shows better transparency than pigment orange 64.

Pigment Orange 72 is with high tinting strength and high saturation, P.O.72 is more yellow and higher saturation compared with pigment orange 64.

Pigment Orange 61 is with mid weather fastness, best light fastness also higher price among orange pigments. P.O.61 exhibits good weather fastness while lower saturation than pigment orange 72.

Pigment Orange 73 is with high tinting strength, high saturation, poor heat resistance/tinting strength in the low concentration; its crystal will mix when used together with pigment red 254. P.O.73 shows better saturation and pure full shade, redder when comparing with pigment orange 64.

Pigment Orange 68 key features are the reddest shade, best heat resistance while low saturation, suited for nylon.

Pigment Orange 43 is of high saturation, high price, excellent lightfastness in low concentration.

Pigment Orange 13 is of most economic choice, poor light fastness, poor immigration resistance, process temperature shall below 200℃.

Pigment Orange 34 is an economic choice which processing temperature shall below 200℃.

all these nine plastic orange pigment technical positions as below

Here we set pigment orange 64 as the standard orange pigment, there is still space in price down with industrialization and potential market share after that. Start from pigment orange 64, if the user needs higher weather fastness, pigment orange 71 and pigment orange 72 is optional. Also, pigment orange 61 with excellent weather fastness both in full and reduction. Pigment orange 34 is extremely bright while limited market share due to high price pigment orange 73 is beating by pigment orange 64 in the market.To save cost, there are pigment orange 13 and pigment orange 34. pigment orange 34 has better properties than pigment orange 13 and redder. PO34 is of low saturation.

How To Choose Pigment Red For Plastic?

How to choose blue shade pigment red for plastic?

Red and yellow are the two big color families of organic pigments. Commerical available organic red pigments for plastic as the chart below, please click on the hyperlink to go to the product page.

[table id=69 /]

There are 11 blue shade red pigments suited for plastics, key features of these plastic orange pigments as below

Pigment Red 122 has high tinting strength, good fastness properties, bright color after reduction, comply with food contact, also price is economic nowadays.

Pigment Red 202 shows better properties compared with pigment red 122 and PR 202 is bluer and darker.

Pigment Violet 19 γ form features are mid tinting strength, good properties, comply with food contact, it looks more yellow than pigment red 122.

Pigment Red 179 exhibits mid tinting strength and mid saturation.

Pigment Red 264 is of high tinting strength and transparent color, P.R.264 is more transparent than pigment red 122.

Pigment Red 177 is of High tinting strength, high-transparent, Mid weather fastness.

Pigment Red 185 is of good light fastness and mostly suited for leather, it belongs to middle properties and middle price.

Pigment Red 176 is of good light properties and mostly used for EVA.

Pigment Red 57:1 is a most economic choice.

Pigment Red 48:2 is of most economic choice, meanwhile it’s heat resistance, light fastness goes down.

Pigment Red 170 F5RK is of high tinting strength, good saturation,cost-effective.

all these 11 plastic bluish red pigment technical positions as below

Here we use pigment red 122 as the standard blue shade red pigment, start from here, pigment red 202 is redder and darker, could used in terylene spinning to solve solubility issue of pigment red 122 in PET. Pigment Red 179 is an option which weather fastness is better while low tinting strength and poor saturation. Pigment Violet 19 γ form, though in same chemistry group, it is yellower than PR122, while tinting strength lower and price higher than PR122. Pigment violet 19 is much better when toning light color. Pigment Red 264 is DPP pigment, the color shade is close to mid red shade. High in price, good transparency, high tinting strength, good weather fastness is three features. Pigment red 177 has extremely good transparency, exhibit bright color when using in PET/PP fiber. Pigment red 176 often used in getting pink color in EVA. Pigment Red 185 is massively used in leather, like automotive interior.

To save costs, pigment red 170 f5rk is the choice, while user shall know its heat resistance, immigration resistance, weather fastness goes downs. Pigment red 48:2 and pigment red 57:1 is the most economic red.pigment red 48:2 suited for PP spun dyeing, widely used in carpet.User shall mind the color changing issue between high and low temperature.

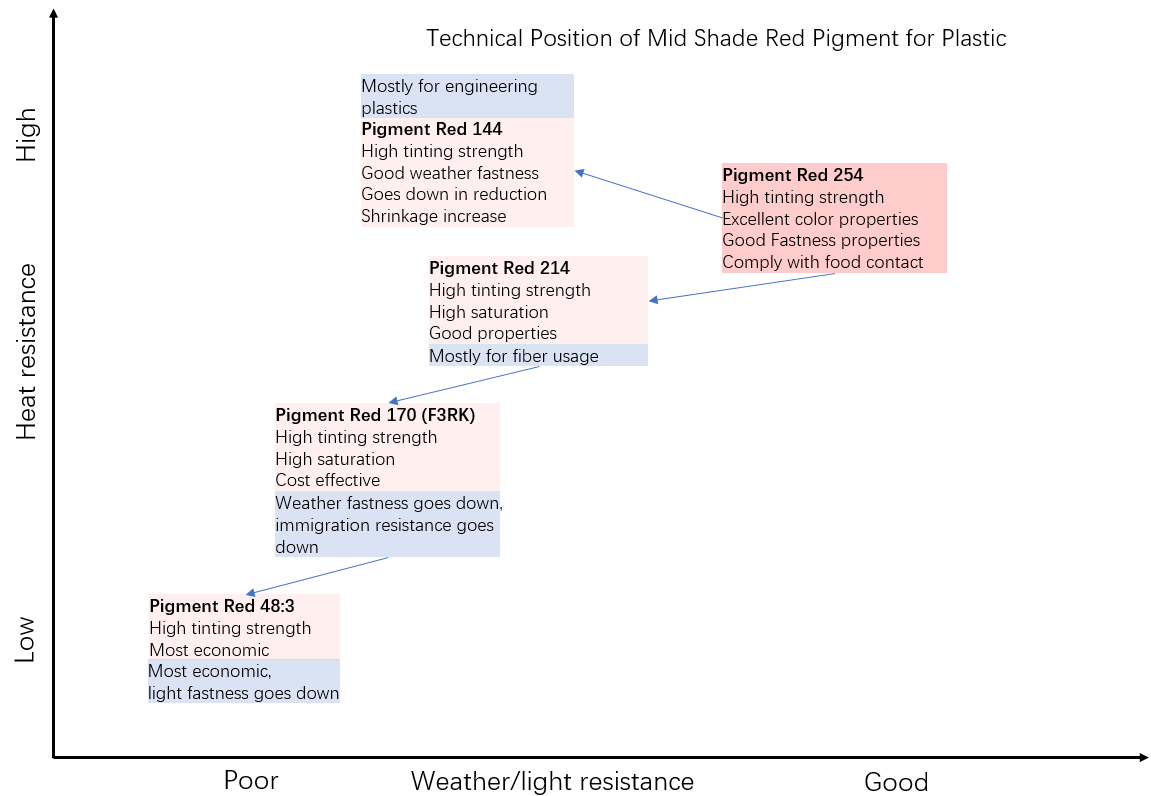

How to choose mid shade pigment red for plastic?

There are 5 middle shade red pigments suited for plastics, key features of these plastic red pigments as below; please click on the hyperlink to go to the product page.

[table id=70 /]

Pigment Red 254 is of high tinting strength, excellent color properties, good Fastness properties, also comply with food contact.

Pigment Red 144 is of high tinting strength, good weather fastness and goes down in reduction, shrinkage increase, PR 144 is mostly used for engineering plastics.

Pigment Red 214 is of high tinting strength, high saturation, good properties, mostly for fiber usage.

Pigment Red 170 (F3RK) is of high tinting strength, high saturation, cost-effective, PR 170 weather fastness goes down, immigration resistance goes down compared with pigment red 214.

Pigment Red 48:3 is of high tinting strength, most economic choice, light fastness goes down when comparing with pigment red 170 F3RK.

all these 5 plastic middle shade red pigment technical position as below

Here we use pigment red 254 as the standard mid shade red pigment; there are 3 grade commercial pigment red 254 available in the market, the small particle size exhibits excellent transparency, the one of big particle size has excellent weather fastness and is taking market share of PR144, PR214, PR170 F3RK. Pigment Red 144 is now used as a complement of PR254 and used in engineering plastics of ABS, PET, PC.Pigment Red 214 is used as a complement of PR254 and used in fiber. Pigment red 254 tinting strength and immigration resistance is better than pigment red 170 F3RK. To save cost, and compromise in heat resistance and light fastness is acceptable, pigment red 48:3 is the choice.

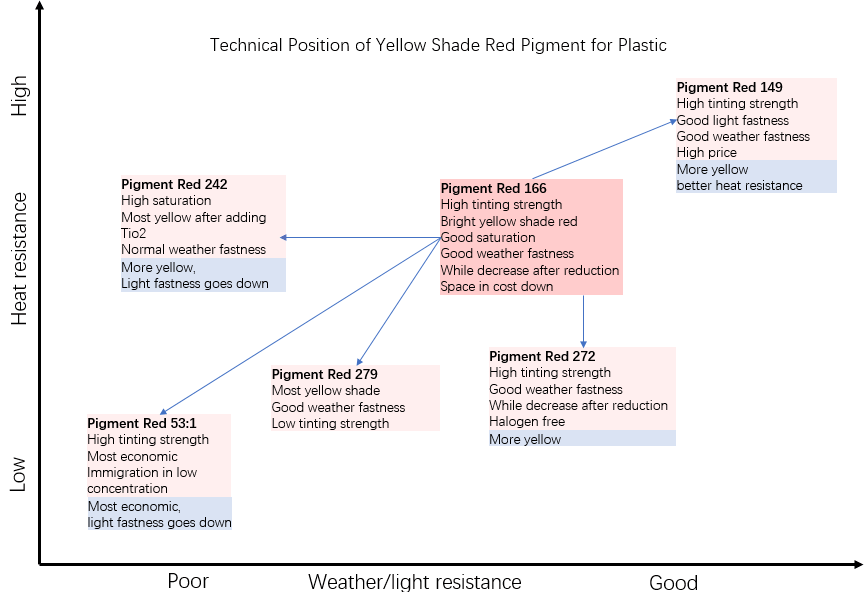

How to choose yellowish pigment red for plastic?

There are total six yellowish red pigments suited for plastics, key features of these plastic red pigments as below,

[table id=79 /]

Pigment Red 166 is of high tinting strength, Bright yellow shade pigment red, Good saturation, Good weather fastness while decrease after reduction, Space in cost down.

Pigment Red 149 is of High tinting strength, Good light fastness, Good weather fastness, High price. PR149 is More yellow, better heat resistance.

Pigment Red 242 is of High saturation, Most yellow after adding Tio2, Normal weather fastness.Compared with pigment red 166, PR242 is More yellow and light fastness goes down.

Pigment Red 272 is of High tinting strength, Good weather fastness, While decrease after reduction, Halogen free.

Pigment Red 279 if of Most yellow shade, Good weather fastness, Low tinting strength.

Pigment Red 53:1 is of High tinting strength, Most economic, Immigration in low concentration.

all these 5 plastic yellow shade red pigment technical position as below

Here we use pigment red 166 as the standard yellow shade red pigment, start from here, pigment red 272 color shade is close to pigment red 166. PR272 heat resistance is relatively lower while saturation is higher when in low concentration. A bright yellow shade is achieved when pigment red 242 and titanium dioxide mixed, it is the first choice when toning high saturation pink-red. To meet a common requirement combined with cost-effective, pigment red 53:1 is recommended, PR 53:1 light fastness and immigration resistance is poor.

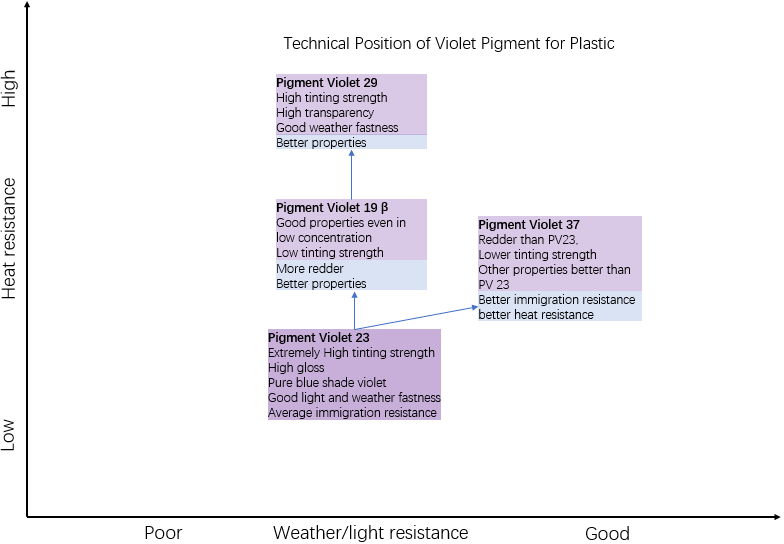

How To Choose Pigment Violet For Plastic?

here are total 4 violet pigments suited for plastics, key features of these plastic violet pigments as below, [table id=80 /]

Pigment Violet 23 is of Extremely High tinting strength, High gloss, Pure blue shade violet, Good light and weather fastness, Average immigration resistance.

Pigment Violet 37 is of Redder than PV23, Lower tinting strength, Other properties better than PV 23, PV37 shows Better immigration resistance, better heat resistance than PV23.

Pigment Violet 19 β is of Good properties even in low concentration, Low tinting strength.it is More redder, Better properties.

Pigment Violet 29 is of High tinting strength, High transparency, Good weather fastness.

all these 5 plastic middle shade yellow pigment technical position as below

Here we use pigment violet 23 as the standard violet pigment for plastic, with commercial success to make it cost reasonable, it is the first choice of violet pigments. If pigment violet 23 not able to meet user’s requirement in a light color, pigment violet 37 is an option. If user need higher heat resistance and better weather fastness, pigment violet 19 β form is a choice, meanwhile shall pay attention to it‘s low tinting strength, red shade and cost increase. Pigment violet 29 exhibits better all-around properties while price is also higher.

How To Choose Pigment Yellow For Plastic?

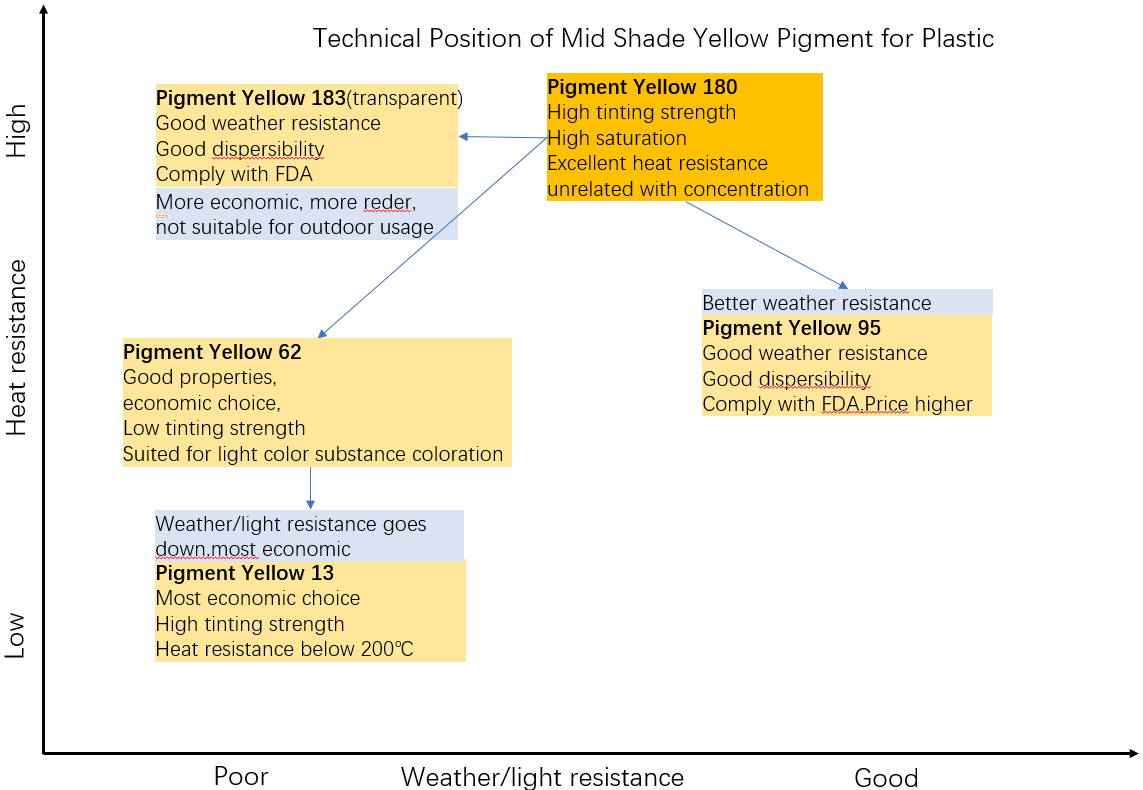

How to choose mid-shade pigment yellow for plastic?

There are total 23 organic yellow pigments suited for plastics, key features of these plastic red pigments as below, among them, five are with mid yellow shade, eleven are green shade yellow and seven are red shade. The five mid-shade yellow

pigment key features are as below.

[table id=77 /]

Pigment Yellow 180 is of high tinting strength, High saturation, Excellent heat resistance, unrelated to the concentration.

Pigment Yellow 183 (transparent) is of Good weather resistance, Good dispersibility, also comply with FDA. PY 183 is more economic and redder than pigment yellow 180 while not suitable for outdoor usage.

Pigment Yellow 62 is of good properties, economic choice, low tinting strength, suited for light color substance coloration.

Pigment Yellow 95 is of Good weather resistance, Good dispersibility, comply with FDA, Price is higher and weather resistance is better when comparing with pigment yellow 180.

Pigment Yellow 13 is of most economic choice, high tinting strength, heat resistance below 200℃. Weather and light resistance goes down, most economic in middle shade yellow pigments.

all these 5 plastic middle shade yellow pigment technical position as below

Here we use pigment yellow 180 as the standard mid-shade yellow pigment, start from here, when need higher weather resistance, pigment yellow 95 is an option which color shade is redder. Pigment yellow 62 tinting strength is half of pigment yellow 180, though the price is lower while weak tinting strength offset this cost-effective effect. To save cost, pigment yellow 13 is a choice, PY13 shows the highest tinting strength, economic in price while common heat resistance and light fastness, limited used due to a safety issue.

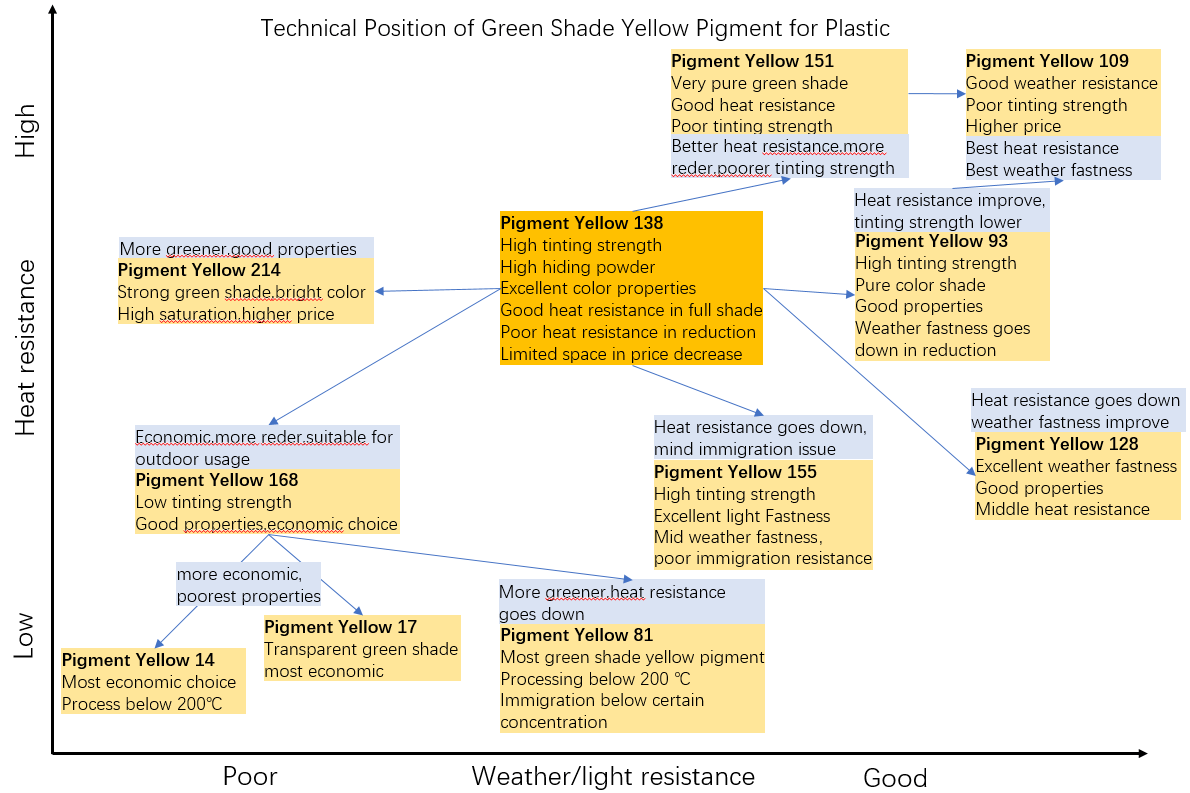

How to choose greenish pigment yellow for plastic?

There are total eleven green shade yellow pigments and key features are as below.

[table id=73 /]

Pigment Yellow 138 is of High tinting strength, High hiding powder, Excellent color properties, Good heat resistance in full shade, while Poor heat resistance in reduction and limited space in the price decrease.

Pigment Yellow 151 is of very pure green shade, Good heat resistance, Poor tinting strength.it shows better heat resistance, more redder, poorer tinting strength compared with pigment yellow 138.

Pigment Yellow 109 is of good weather resistance, Poor tinting strength, Higher price. PY109 exhibits best heat resistance and best weather fastness among these green shade yellow pigments.

Pigment Yellow 93 is of high tinting strength, Pure color shade, Good properties while Weather fastness goes down in reduction. PR 93 heat resistance improves and tinting strength decrease when compared with pigment yellow 138.

Pigment Yellow 214 is of strong green shade, bright color, high saturation, higher price. PY 214 is more greener and better properties than pigment yellow 138.

Pigment Yellow 168 is of low tinting strength, good properties, economic choice. redder than pigment yellow 138 and suitable for outdoor usage.

Pigment Yellow 155 is of high tinting strength, excellent light Fastness, Mid weather fastness, poor immigration resistance. PY155 heat resistance goes down when compared with PY138, what’s more, the user shall pay attention to the immigration issue when using it.

Pigment Yellow 128 is of excellent weather fastness, good properties and middle range heat resistance.compared with pigment yellow 138, PY 128 heat resistance goes down while weather fastness improve.

For more economic, while poor properties choices, there are pigment yellow 14 and pigment yellow 17.

Pigment Yellow 14 is of most economic choice and shall process below 200℃.

Pigment Yellow 17 is of transparent green shade, most economic green shade yellow pigment for plastic.

Pigment Yellow 81 is of most green shade yellow pigment, processing below 200 ℃, PY 81 immigrate below a certain concentration, PY 81 is greener and heat resistance goes down from pigment yellow 168.

all these 11 plastic green shade yellow pigment technical position as below

Here we use pigment yellow 138 as the standard green shade yellow pigment, start from here. When better weather fastness is needed, pigment yellow 128, pigment yellow 93, pigment yellow 151, pigment yellow 109, PY109 is primary, pigment yellow 128 ranks second and mind the heat resistance, pigment yellow 93 is fine, also mind color shade is red. PY151’s heat resistance and weather fastness are better while tinting strength is lower. To save cost, pigment yellow 155 is an option, user shall mind the immigration issue when using it. To further save cost, pigment yellow 168 is a wise choice, also pigment yellow 17 pigment yellow 14, pigment yellow 81, these are the most cost-effective. User shall mind the Dichloro benzidine safety issue, process temperature below 200℃, what’s more, immigration issue of pigment yellow 14 is an issue.

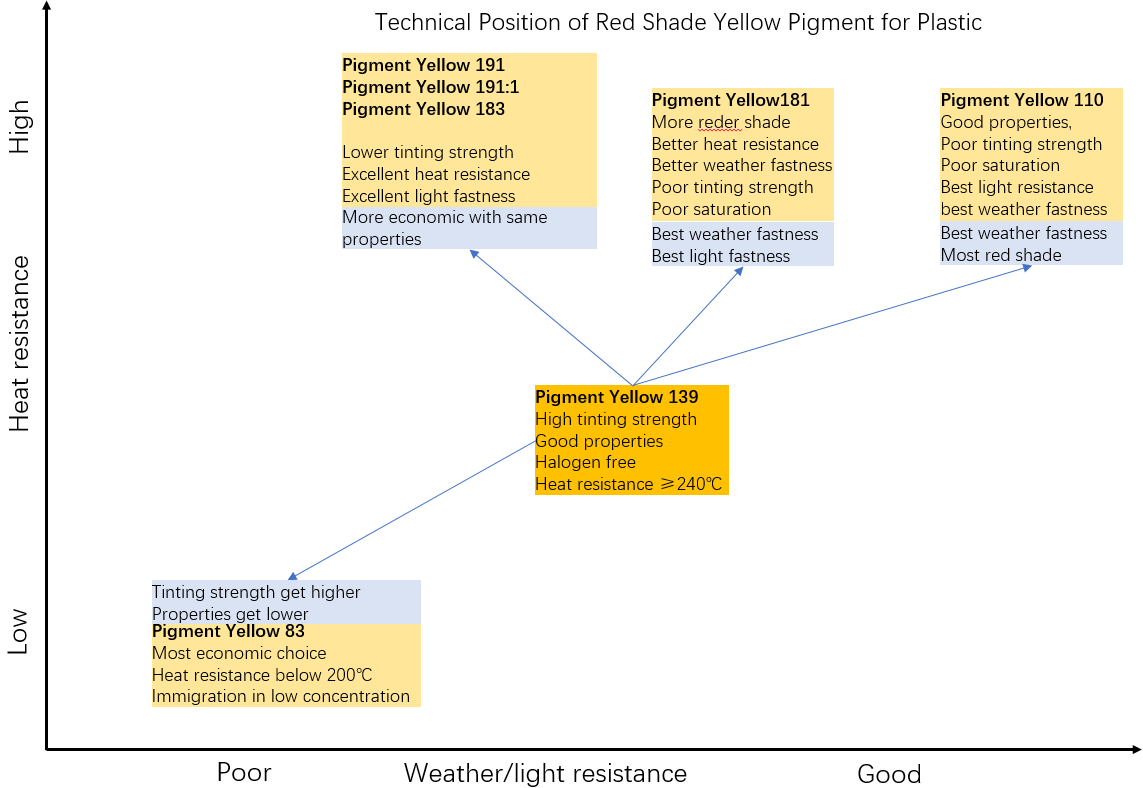

How to choose reddish pigment yellow for plastic?

There are total 7 red shade yellow pigments and key features are as below.

[table id=74 /]

Pigment Yellow 139 is of high tinting strength, good properties,halogen-free, heat resistance ≥240℃

Pigment Yellow 191, Pigment Yellow 191:1 and pigment yellow 183 shows lower tinting strength, excellent heat resistance, excellent lightfastness. These three are more economic with same properties.

Pigment Yellow 110 is of good properties, Poor tinting strength, Poor saturation, Best light resistance, best weather fastness and most red shade pigment yellow.

Pigment Yellow 83 is of most economic choice, heat resistance below 200℃, Immigration in low concentration. comparing with pigment yellow 139, PY 83 tinting strength get higher and properties get lower.

all these 7 plastic red shade yellow pigment technical positions as below

Here we use pigment yellow 139 as the standard red shade yellow pigment, start from here, there are various pigment in red shade yellow pigment zone. If user need high heat resistance and better weather fastness, pigment yellow 181 is an option which excellent heat resistance in low concentration. PY181 exhibit low tinting strength and high in price, low saturation after reduction. Pigment yellow 110 is redder, better heat resistance and weather fastness, even lower in saturation. To save cost, there are pigment yellow 191 and pigment yellow 183 which both are poor water resistance, PR183 water resistance is better than PR191 while PR191 heat resistance is better than PR183. Pigment yellow 83 is of high tinting strength, good saturation and fine heat resistance, it is the first choice to save costs, the user shall mind the safety issue of Dichloro benzidine when choosing.

How To Choose Pigment Blue For Plastic?

There are four blue pigments for plastics, and key features are as below.

[table id=78 /]

Pigment Blue 15:1 is of high tinting strength, pure red shade pigment blue, high light and heat resistance.

Pigment Blue 15:3 is of high tinting strength, pure green shade pigment blue, high light and heat resistance.

Pigment Blue 15:0 is of high tinting strength, pure red shade pigment blue, good light and immigration resistance, heat resistance 200℃. Due to PB 15 is a not stable crystal structure and heat resistance goes down.

Pigment Blue 60 is of pure red shade pigment blue, good properties, suited for nylon, excellent weather resistance. Redder & better weather resistance than pigment blue 15:1.

all these 4 plastic blue pigment technical position as below

Here we use pigment blue 15:1 as the standard blue pigment, the commercial production makes it’s price acceptable. Pigment Blue 15:3 is β form and stable than pigment blue 15:1, thus, properties is also better. It is widely used in plastics. When a user can’t achieve brighter red color with red, blue pigment, pigment blue 60 is the option, costs increase as well. Pigment blue 15 is most red among all phthalocyanine pigments, only recommend when common heat resistance, red shade, high tinting strength is needed, for example, EVA forming.

Global And China Organic Pigment Market

1. Global and China Economic Introduction

Global growth rate slowing to 2.4 percent in 2015 from 2.6 percent in 2014. It is estimated that global growth is projected to edge up, and is expected to reach 2.9 percent in 2016-17 and 3.1 percent in 2017-18. China.Even with the decelerated GDP growth rate which described as “the New Normal”. China’s economy is expected to grow between 5.5% and 6.5% annually. The chemical market in China is by far the largest in the world and will make up two-thirds of the total growth of the global chemical market over the next five years.

2. Global Organic Pigment Market Scale

2.1 Global and China Organic Pigment Market Scale

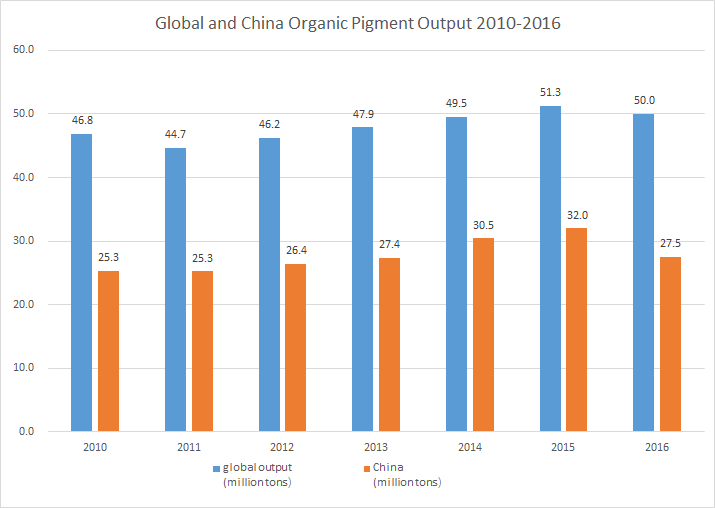

From the Year 2011 to 2016 period, As the chart below

Source: 1. China Dyestuff Industry Association Organic Pigments Professional Committee (unit million tons) 2. China Customs Data

In the year 2010, global organic pigment output is 46.8 million tons (MT) and China produced 25.3MT among them, the next year of 2010, global output declined to 44.7MT, China keep the same output as the year 2010, In 2012, global organic pigment output bounced back to 45.2MT and China increased to 25.4MT as well.In 2013, the increase continues, global data is 47.9MT, and China production is 27.4MT.Next year, global output climbed to 49.5MT and China makes 30.5MT.In the year 2015, both hit its peak in period 2010-2016, global data is 51.3MT, and China is 32.0MT. In the year 2016, with the environment administration been strict, a large number of small to medium factories been shut down and this year, global output is 50MT, and China declines to 27.5MT.

2.2 India Pigment Market Scale

India pigment market scale reaches 0.454 billion USD in the Year 2015.Among them, blue and green pigment take the majority in the color segment. For high-performance pigment which key intermediates import from China, it’s still in the incubation period. Source: annual report of 2015-2016 Sudarshan

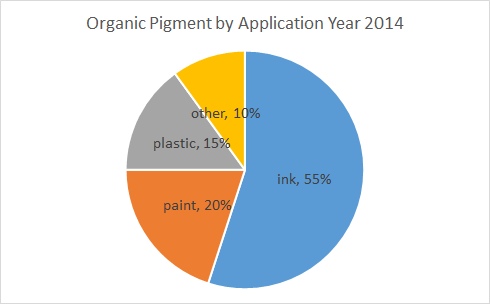

3. Global Organic Pigments Market By Application

As chart below,which ink is about 55% ,paint takes about 20%,plastic is 15% ,other applications is 10%. Chart above represents overall structure recently. Segmentation by application may contain various in vendors and countries and shall change over time.

4. Global Organic Pigments Market by Type

4. Global Organic Pigments Market by Type

4.1 Classical pigment which stands for organic pigment excepts high-performance ones; it’s quantity ratio is 80-85%, sales revenue proportion is about 70-75%.

4.2 HHP abbreviation of high-performance pigment which includes high performance azo and high-performance heterocyclic, on the contrary, makes 10-12% in quantity while sales revenue proportion has reached about 25-30%.

5.Global organic pigments market trend

5.1 Organic Pigments Industry Trend

Before the 1980s, Europe and the United States had played a leading role in manufacturing. After the 1980s, production gradually transferred to Asia mainly China and India. In Recent years, there is a capacity excess of organic pigment worldwide. Industries in unorganized sector account for a large share in the production of pigments. This results in intense price competition in the commodity segments market.

5.2 Organic Pigments Technological Trend

There is still a big gap between China’s organic pigment industry compared with prominent vendors (BASF, Clariant, DIC). Though China’s organic pigment production and export volume ranked first in the world, it’s product structure remains to be improved.

6. Global organic pigments market forecast 2017 to 2021

The global organic pigments market to grow at a CAGR of more than 3% to 3.5% between 2017 and 2021 main production areas includes China, India.we assume China pigment industry trends as follows

● concentration of organic pigment segment will increase;

● vendors getting lessen;

● profitability getting better.

Legislations And Regulations of Organic Pigment

Legislation and regulations for pigments are primarily related to food packaging, consumer goods and toys. Two general principles must be satisfied;

1. The pigment producer has to assure his customer that the pigment is toxicological of no concern.

2. The manufacturer of the pigmented articles must guarantee that the pigment neither migrates into food nor migrates from consumer goods or toys.

Main Legislation Concerning Organic Pigments

Food Packaging

Materials and articles intended to come into contact with foodstuff are generally regulated in the EU in the Framework Directive 89/109/EEC. Under this Directive Single Directives are released, such as for Plastic Material (90/128/EEC), Cellulose Films (83/229/EEC), Elastomers and Rubber (93/11/EEC) and others. Directive 89/109/EEC generally requires that the constituents of all food contact material do not transfer to the foodstuff in quantities which could endanger human health.

European Union AP (89) 1 (1989)

Council of Europe Resolution AP (89) 1 (1989)

- The maximum threshold limits of metals or metal ions soluble in 0,1 m hydrochloric acid is as follows: Metal ppm Metal ppm As 100 Hg 50 Ba 100 Pb 100 Cd 100 Sb 500 Cr 1000 Se 100.

- The trace amount of primary aromatic amines, which are soluble in 1 m hydrochloric acid, must be lower than 500 ppm (expressed as aniline). ETAD*) developed a testing method for aromatic amines.

- The threshold limit for aromatic amino sulfonic acids expressed as aniline sulfonic acid, must be below 500 ppm.

- For benzidine, 2-naphthylamine and 4-aminodiphenyl the threshold limit is 10 ppm.

- The trace amount of polychlorinated biphenyls (PCB) should not exceed 25 mg/kg.

EU 94/62/EEC

The concentration limits of lead, Cadmium, Mercury, and Chromium (VI) in packaging material or components of packaging material are not allowed to exceed 100 ppm (cumulative). This is in force since June 30, 1994.

The Scientific Committee for Food (SCF) lays down for toxicological evaluation of food contact substances three levels of toxicological tests dependent on the amount of migration (mg/kg food simulant): Level 1: < 0.05; level 2: 0.05-5; level 3: >5.

USA CONEG Regulation

nearly same as in 94/62/EEC (see above).

Other Countries

Several countries have released identical or similar regulations as the European Regulation AP (89)1 regarding the threshold limits for metals, aromatic amines, aromatic amino sulfonic acids and PCB.

Toys

On a national basis, Toys require compliance of limits for the same impurities as outlined under food packaging. In particular trace, metal amounts have to be considered as well as threshold limits for aromatic amines, soluble in 0,07 m hydrochloric acid. The trace amount of cancerogenic amine should depend on the various countries, not exceed 5 or 10 ppm.

European Union EN 71-3 (1994)

European Toy-Norm EN 71-3 (1994), with different threshold limit levels.

USA FDA

comply with FDA paragraphs 21 CFR 178, 3297 and apply for FCN(Food Contact Notifications)

Other Regulations Related

REACH & SHVC List

PREN 14582

All halogen element shall below 50ppm

EN-50268-2

- Cl<900ppm, Br<900ppm

- Cl+Br <1500

2002/95/CE ROHS

Restriction of Certain Hazardous Substances (ROHS)

Aim: Electrical and electronic products bearing the CE mark shall meet ROHS 2.0 directive which effective since Jul.21st.2001

Pb <1000ppm

Hg <1000ppm

Cr VI <1000ppm

Cd <100ppm

PBB <0

PBDE <0

Automotive Materials EU 2000/53/EC Directive

EU 2000/53/EC Directive

From 2003 Jun 1st, Automotive materials shall without Pb, hg,Cr(VI), Cd except for listed exceptions.

Other Substances Related

Polychlorobiphenyls (PCB)

Strict legal limits have been defined in some countries (for instance in the USA, and also throughout the European Union) because of the persistency and the wide distribution of these compounds. These regulations have primarily been issued to protect the environment, less because of a direct hazard to humans. Legislation 592 PCB traces may be found in two groups of organic pigments, namely in – azo pigments derived from chloroaniline or dichloro or tetrachlorodiamino- diphenyl, which may undergo various side reactions that produce traces of PCB, – pigments which are manufactured in the presence of dichlorobenzene or trichlorobenzene as a solvent. In this case, PCB may be formed through radical reactions.

Polychlorinated Dioxins/Furans (“Dioxins”)

Similar conditions as for the formation of PCB’s might also lead to the formation of small trace amounts of dioxins. A German Hazardous Substances Ordinance (Chemikalien-Verbotsverordnung) prohibits to place products on the market for which very low limits of dioxin traces are exceeded. Regulated dioxins are those who at least are tetrachloro (or promo) substituted in 2,3,7,8-position Phthalates

Phthalates

2005/84/EC Directive

Sign Up for Our Newsletter!

[contact-form-7 id=”2272″ title=”Sign Up to Our Newsletter!”]