How Does UV absorber Work? mechanism of UV absorber

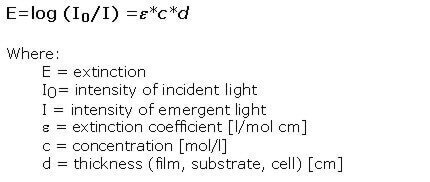

The main function of UV absorbers is to absorb UV radiation in the presence of a chromophore (Ch) found in the polymer, the aim is to filter out the UV light that is harmful to the polymer before chromophore free radical Ch* has had a chance of forming. Above all, a UV absorber must function within the 290 and 350 nm range. The effectiveness of UV absorbers is determined not only by their absorption characteristics but also, above all, by the Lambert-Beer Law.

Synergistic Effect Of Light Stabilizers And UV Absorber

UV absorbers are not able to absorb all of the UV radiation that a coating is exposed to. Some UV radiation will penetrate the coating surface. Because of this, HALS are incorporated into the polymers. These molecules work by scavenging any free radicals that do form – this is different from UV absorbers, which prevent their formation in the first place HALS function by removing radicals from the system and subsequently regenerating themselves. Most formulators will use a combination of absorbers and HALS for this reason.

Synergistic combinations of UV absorbers and HALS are optimal for the stabilization of polymer. UV absorbers are governed by the Beer-Lambert Law, thus absorbance is linearly related to the concentration of UVA (320 to 400 nanometers (used for photocuring), its molar absorptivity (extinction coefficient), and path length (coating thickness). HALS are free radical scavengers and are not subject to Beer’s Law and work anywhere in the coating system. HALS are especially effective at coating surfaces, providing better gloss retention, higher chalking resistance in pigmented systems while avoiding crack formation in clear coats. For pigmented systems, HALS provide the primary mechanism of stabilization because most UV radiation is blocked by pigment from penetrating beyond the first few microns of a coating. The selection of the appropriate UVA/HALS combinations and concentration is dependent on the chemistry of polymer application system, the presence of pigments and fillers, film thickness and exposure conditions.