Chain Extender BX ADR 3700

Introduction

Molecular weight: 6500-7200

CAS No.: 1191261-43-4

Appearance: white powder or granules;

Epoxy equivalent: 280-310 g/mol

Chemical name: Styrene (ST), methyl methacrylate (MMA) and glycidyl methacrylate (GMA) copolymer

English name: 2-Propenoic acid, 2-methyl-,oxiranylmethyl ester, methyl methacrylate, polymer with ethenylbenzene

Equal to: BASF Joncryl ADR 4370

Product Description

BX ADR 3700 is a polymeric epoxy functional chain extender. The epoxy functional group in its structure can achieve chain extension of the polymer by reacting with the terminal hydroxyl group, carboxyl group, and amino group in the condensation polymerization resin, thereby improving the performance of the condensation polymerization resin. Characteristic viscosity, mechanical properties, and the purpose of inhibiting polymer hydrolysis.

Key Applications

Chain Extender in RPET

Epoxy chain extenders play a crucial role in recycled PET(RPET) by restoring molecular weight and enhancing mechanical properties such as tensile strength and impact resistance. They improve processability during manufacturing and enhance compatibility in polymer blends, making recycled PET suitable for high-performance applications like packaging, textiles, and automotive components. This results in recycled PET performing similarly to virgin PET, thus promoting sustainability and expanding its application range.

Chain Extender in PLA/PBAT

Epoxy chain extenders play a crucial role in enhancing the properties of PLA (polylactic acid) and PBAT (polybutylene adipate-terephthalate) blends. They react with the chemical groups of these polymers, increasing molecular weight and improving mechanical properties like tensile strength and flexibility. This results in better processability during manufacturing and improved performance in final products. Epoxy chain extenders also enhance the compatibility between PLA and PBAT, creating more homogeneous blends that exhibit superior overall properties, making them suitable for applications such as packaging and biodegradable materials.

Applications

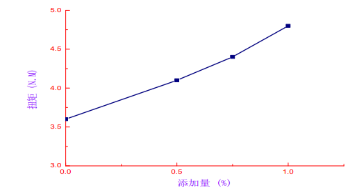

Chain extender BX ADR 3700 modification:

70% PBAT+30% PLA mixture, 195℃

70% PBAT+30% PLA mixture, 195℃

Dosage

① The recommended dosage in bio-based and biodegradable plastics such as PLA, PPC, PBS, PHA, etc. is 0.2-1.5 wt%;

②The recommended dosage in polycondensation recycled plastics such as PET, PBT, PC, and PA is 0.2-2.0 wt%.

③ The specific dosage depends on the number of active functional groups in the resin and product performance requirements.

Baoxu Chain Extender additives

| Item | Epoxy equivalent weight (g/mol) | Mw | Tg (°C) | Equal to BASF | Epoxy equivalent weight (g/mol) | Mw | Tg (°C) |

| BX ADR 3700 | 280-310 | 6500-7200 | / | joncryl ADR 4370 | 285 | 6800 | 54 |

| BX ADR 4300 | 430 -460 | 5500-6000 | 56 | Jonciyl ADR 4300 | 445 | 5500 | 56 |

| BX ADR 4370 | 270-300 | 6500-7000 | 61 | joncryl ADR 4370 | 285 | 6800 | 54 |

| BX ADR 4370 | 270-300 | 6500-7000 | 61 | joncryl ADR 4380 | 450 | 3300 | -41 |

| BX ADR 4370 | 270-300 | 6500-7000 | 61 | Joncryl ADR 4385 | 450 | 6000 | -37 |

| BX ADR 4370 | 270-300 | 6500-7000 | 61 | Joncryl ADR 4468 | 310 | 7250 | 59 |

| BX ADR 4370 | 270-300 | 6500-7000 | 61 | Joncryl ADR 4400 | 485 | 7100 | 65 |

| BX ADR 4470 | 1330-1530 | 35000-40000 | 94 | / | / | / | / |

Proceeding guide of chain extender agent baoxu

Storage, transportation, and packaging

In a ventilated and dry environment, the shelf life is two years. Net weight: 20kg/bag, lined with PP film.

health safety

Acute oral toxicity test in mice: The oral LD50 of chain extender BX CE 3700 to both male and female mice was greater than 5000 mg/kg.bw, which is a low-toxicity substance. This product should be handled and used to avoid dust formation and keep away from sources of fire.