Cross-linking(Vulcanizing) agent BIBP

Introduction to Organic Peroxide

Organic peroxides are derivatives of hydrogen peroxide, which function as

- Initiator for the production of thermoplastics such as PE, PVC, and EPS

- Curing agent for thermoset resins

- Crosslinking agent for elastomers and thermoplastics

- Modifying agents for polymers such as polypropylene

- Reagent in pharmaceutical synthesis

Baoxu Bibp vs Brands

| chemical name | Nouryon | Arkema | NOF | Baoxu |

| Di(tert-butylperoxyisopropyl)benzene | Perkadox 14S-FL | LUPEROX F | PERBUTYL P | BX CA BIBP |

Cross-linking agent BIBP Properties

Trade Name: Cross-linking agent BIBP

Common Name: BIBP, vulcanizing agent bibp, odorless DCP, peroxide bibp, initiator bibp

Chemical Name: Bis(t-butyl peroxy isopropyl)benzene

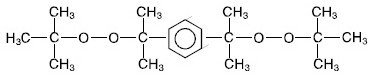

Formula : C6H4[C(CH3)2OOC(CH3)3]2

Chemical Structure:

Molecular Weight: 338

CAS NO : 25155-25-3, 2212-81-9

Density: 1.08g/cm3

Boiling point: 360℃

Melting point: 44-48℃

Active oxygen content: 9.1-9.6%

Half-life data Activation energy: 152.69KI/mol

10 hours half-life temperature: 114℃

1 hour half-life temperature: 134℃

6 minute half-life temperature: 156℃

Safety data

Flash point:113℃

SADT.: 80℃

Alarm temp.: 75℃

UN CODE 3106

HS Code 29096000

Application of BIBP

As Initiator and MFR Modifying agent in polypropylene

When used in polypropylene pp, BIBP can be functioned as

● Degradation Agent for polypropylene processing

● MFR modifier to produce fiber-grade polypropylene

● Petrochemicals, for example, for the production of Non-woven fiber and melt-blown fibers grade PP.

● PP Compounding to create higher MFR

● Co-agents in PE and Ethylene copolymer grafting

● Initiators for MAH grafting

As a Cross-linking agent bibp in rubber

1. Generally, DCP vulcanized products have an unpleasant smell. If BIBP is used, it can be used as a 2:3 substitute for DCP products with almost no odor, so it is commonly known as odorless DCP. It is especially suitable for products with strict odor requirements. Used as a vulcanizing agent for ethylene-propylene rubber, ethylene-propylene-diene rubber, nitrile rubber, silicone, and polyurethane rubber.

2. If used in nitrile rubber, the dosage should be reduced due to the high vulcanization efficiency.

3. It can improve the heat resistance of vulcanized rubber, improve compression deformation, and improve low-temperature flexural performance. Because the melting point of Perkadox14 is higher than that of DCP, when used in EPDM, it should be melted first and then added to the rubber compound, or mixed at high temperature. Because the sulfide decomposition products of BIBP have poor compatibility with EMDM, they sometimes migrate from the inside of the product to the surface to form needle-like crystals that bloom. It is best not to use more than 3% in EPDM. Use it together with the bridging aid TMPTMA or TAIC to reduce the blooming phenomenon.

4. Particularly suitable for EPDM rubber, ethylene-coylate copolymer, nylon elastomer, POE elastomer, OBC elastomer, silicone rubber, hydrogenated nitrile rubber, rubber, perfluoroether rubber, fluorinated polyethylene, XPU exchange It is widely used in polyurethane rubber and other industries. It is especially recommended for shoe material injection molding, supercritical foaming and other applications.

Handling and storage

Packed in a carton with 2*10KG PE bags inside, N.W.:20KG. Keep away from direct sunlight, heating, violent shaking, strong acids, and reductive agents during transportation or storage.